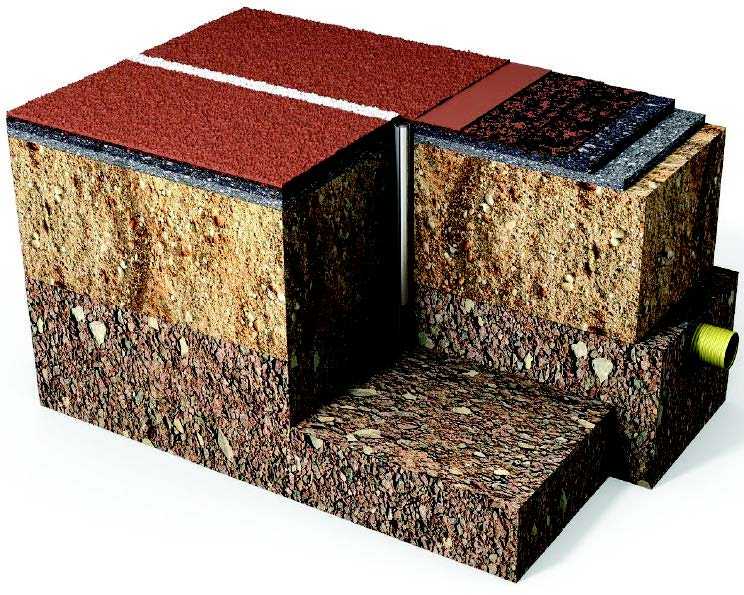

FieldTurf's fibre, which combines a variety of polymers, has a hardened centre and a soft outer layer to offer a resilient and durable surface with optimal player-friendliness and player-surface interaction. The technology was installed in the pitch at Hartsdown Park Stadium by Margate Football Club last summer. In tests by Labosport, specialists in sport surface certification, the surface achieved the highest ever FPI (Fibre Performance Index) score, which measures durability, resilience and softness - with a score of 89.

The benefits

Not only has it enabled the club an additional revenue stream but the players feel the difference. “The pile allows the ball to zip across the surface quickly and our players have noticed a big difference between our surface and others. Players complain about some of the other 3G pitches being too firm which causes a problem with change of direction and they do not find this issue with ours” says Chris Chambers of Margate Football Club.

A fantastic home playing surface for all

"We cater for senior teams, our post 16 academy, u23 development squad, ladies and u18 teams. In addition, we can now accommodate the majority of our youth sections on the pitch throughout the week for training, our mini gators soccer club on the pitch on a Saturday prior to home matches as well as differing community groups and one off charity events. All this without an adverse effect on the ability of the first team to play, unlike grass which would never have been able to withstand the level of use”.

The Core system is certified to FIFA Quality, FIFA Quality Pro and World Rugby. This core fibre technology has been installed across Europe including: FC Augsburg, Mainz 05, Teistungen, Koln Klettenberg, Maintal and Unter Flockenbach in Germany, VVOR Rotterdam and Feyenoord Rotterdam in Holland and Herenthout in Belgium.

Smart athletics track monitors performance

Kingsmeadow Athletics Centre in Surrey is one of the latest venues to install smart technology to provide performance data for field and track users.

The data logging system from Polytan provides training diagnostics without costly technical installations. Known as SmarTracks, the system combines three components: magnetic timing gates built invisibly into the track, a waist belt with sensor and analysis software.

The technology can be used to record the movement data of several athletes simultaneously measuring the athlete’s speed, length of stride, step frequency and jump height.

The movement data is captured by timing gates located in the ground and the sensor, which weighs just 24g, worn on the body. Two round magnetic elements (600mm long and 25mm thick) are sunk into the ground at intervals of 1m to 1.30m to form a timing gate. The upper end of the magnetic elements lies no more than 25mm beneath the upper edge of the synthetic surface. One track needs two magnetic elements, two tracks need three, three tracks four and so on. A minimum distance of 3m between the timing gates in the running direction is recommended.

Benefits of the sensor technology include low measuring tolerances, full protection against vandalism, a complete lack of dependence on weather conditions and no time-consuming setup and dismantling of technical equipment.

The system is suitable for all outdoor synthetic surfaces from Polytan and can also be retrospectively incorporated into existing athletics facilities.

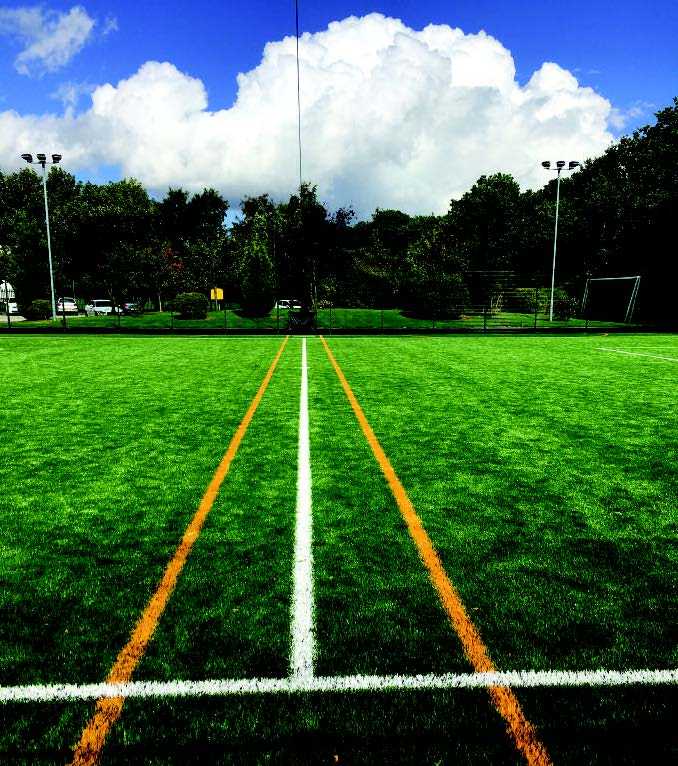

Purpose-built competitive walking football pitch

Solihull Football Centre, home to the Birmingham Walking Football Club, has installed a 3G pitch specifically designed to cater for the competitive needs of walking football in response to growing demand for the activity.

Aimed at the over 50s, with many tournaments catering exclusively for the over 60s, walking football forbids all running and allows either no contact or only minimal physical contact between players who walk briskly through matches.

The centre worked with Synthetic Turf Management to create a six/seven a-side walking football championship pitch that comprises a lined 38m x 31m playing surface, 5.5m Ds, 6m penalty spot, and 12ft x 4ft goals.

Synthetic Turf Management transformed an existing synthetic bowling green with a 60mm pile height product in-filled with a layer of silica sand at the bottom followed by the rubber crumb on top, to help protect the blades of grass. The installation also included white and yellow line markings which were cut into the artificial grass as permanent lines.

Three months following the installation, the centre owners have reported an increase in pitch hire, with local teams using the facility and walking football sessions set up weekday, evenings and weekends.