From the outside, the building resembles a block of ice thanks to its striking facade, which provides the insulation required to keep the building running efficiently. The project took a total of 21 months to build, opening in February 2018 with more than 8,000 people trying out the new facilities for free on the open day. The centre is operated by Everyone Active.

Background

Romford’s new £28m Sapphire Ice & Leisure Centre is the town’s first leisure facility since the Dolphin Centre closed in 1995. It re-introduces an ice rink to the town. In 2013, Romford Ice Arena closed, leaving the town without an ice facility for the first time since the 1980s. Figure skaters and local sports teams were forced to relocate, including ice hockey team Romford Raiders, who moved to Leyton, East London, changing its name to London Raiders.

Funded by the London Borough of Havering (£26m) and Sport England (£2m), the scheme forms part of a larger land-swap arrangement with a national supermarket chain where the site of the old ice rink will become a new supermarket.

The new facility is the flagship of the Borough Leisure strategy and has been integral to the council’s newest Leisure Facilities Operations contract, which has been recently procured.

The scheme’s objectives

“The council’s primary focus with this non-statutory service is ‘Spend to Save’. But a number of secondary objectives were necessary to achieve the first,” says Nathan Swift, director at Saunders Boston Architects.

These included the location. High land values, limited local authority resources and tight budgets constrained the physical area of the site that could be acquired.

Innovative design

We had to find a way of fitting a facility of this size into a restricted site with limited build space. To achieve this, our design became one of only a handful in the UK where the entire ice rink is located directly over a swimming pool hall, breaking with the norm of them sitting side by side on the ground floor” says Swift.

Structural and thermal challenges

The architects needed to address two fundamental concerns: dealing with the large span/minimal tolerance structure alongside a requirement for a warm, high humidity swimming pool and a cool, low humidity ice rink.

“Close collaborative research was required between ourselves, the structural engineering designers, the mechanical and electrical designers, several specialist consultants, the contractor and manufacturers/suppliers of the external and internal fabric to ensure that we fully understood the technological uncertainties encountered in the project design. Having understood these we developed designs to solve the uncertainties and ensured that these are co-ordinated between all disciplines” says Swift.

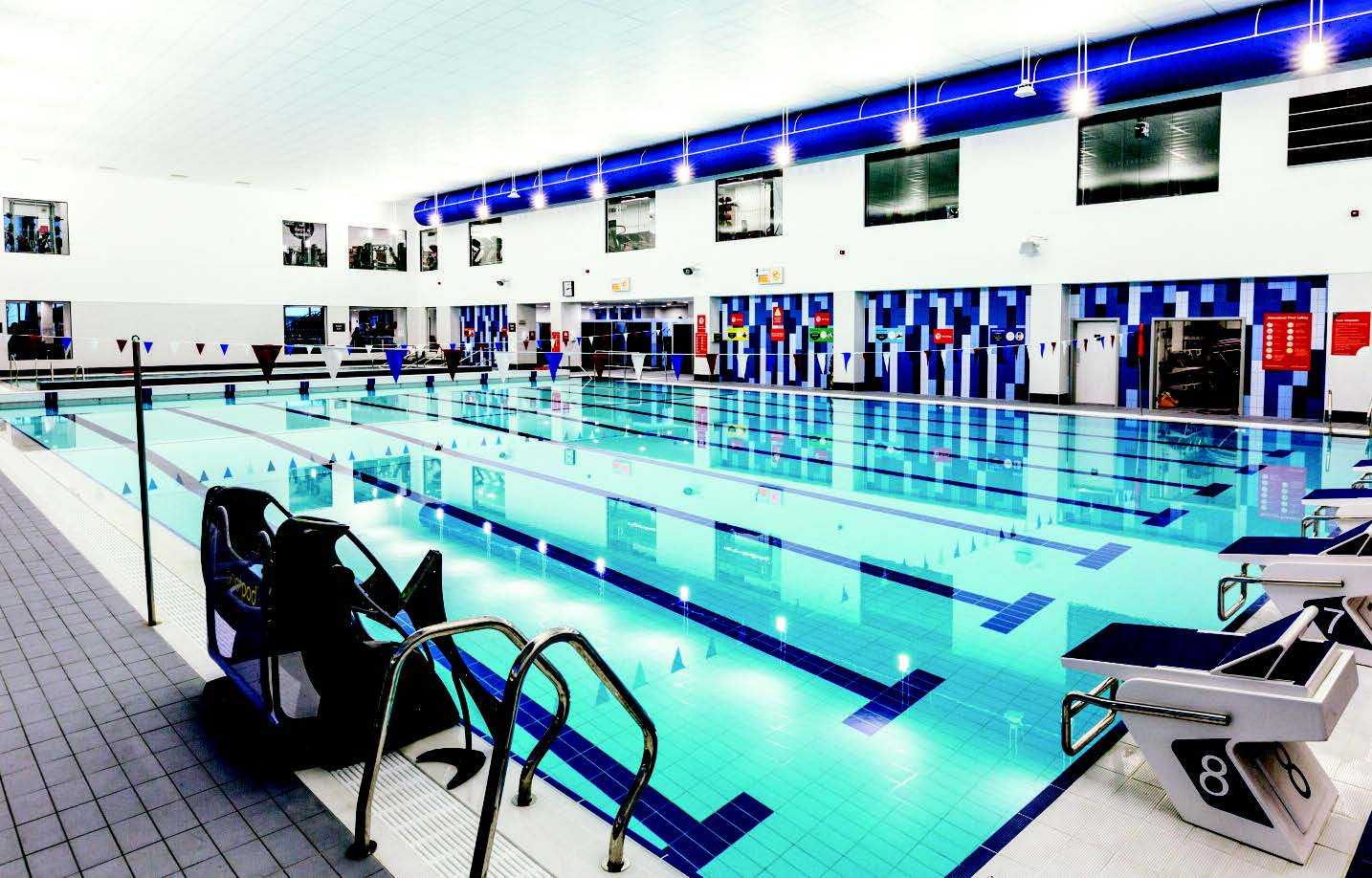

The main pool tank at ground floor level is 17m wide, when adding pedestrian surrounds and spectator seating the primary structure supporting the ice rink needs to span over 25 metres. The final two metres are a cantilever which adds additional complication to the design. To prevent the ice from cracking, the tolerances and ‘deflection’ (bending of the slab) must be kept to a minimum (circa 5mm to 10mm over the length of the ice rink).

Temperature control

The challenge

The temperature in the pool hall has a controllable range between 25 and 30 degrees Celsius, whilst the ice rink floor needs to be kept ‘frozen’ with an ambient air temperature around 18 degrees Celsius. Therefore between the two environments controlling the temperature change and interstitial condensation are critical.

The solution

The team, which also included a specialist Condensation Analyser, developed an innovative proposal which combined a structural and environmental solution incorporating:

Multiple computer simulations of this construction were carried out to confirm how the build-up would respond to changing weather conditions throughout the year. In the event of the ice plant failing the upper slab was also designed to retain the melted water from leaking into the pool hall below.

Glare and pool safety

The challenge

“Controlling thermal performance of spaces within the building is essential to the success of the facility. Excess glare in the pool hall can create significant health and safety issues in the pool hall because low sun, reflecting off the surface of the water, can make it extremely difficult for lifeguards to see the bottom of the pool where someone might be in distress,” explains Swift.

The team could not find an existing system that resolved all the scientific and technological challenges presented in this particular situation whilst delivering the high quality and safe environment desired.

The solution

Much research led to a proposal to bring together two new technologies:

A Polycarbonate wall/rainscreen double-skin cladding

“Using Everlite polycarbonate panels (manufactured on the Continent) allows natural, UV filtered, light into the space without the glare in a double-skin scenario to improve the U-Value (thermal performance). This is the first time this product has been used in this way in the UK and we are now looking to use it on three other schemes” says Swift.

Drowning detection system

Constructed by Willmott Dixon, Sapphire Ice & Leisure Centre is one of the first new-build centres in the UK to be fitted with AngleEye, an automated drowning detection system. It uses optical devices, mounted above and below the water line, which relay information about the swimmers behaviour. The system automatically detects a person in a potentially dangerous situation that may require assistance. An alarm is generated on a hand held device identifying where within the pool the incident is, allowing the poolside lifeguard to respond to the situation.

Safety in wet areas

Floor finishes in pool changing and pool surround areas present a common problem. The ultimate solution - total slip resistance combined with easy cleaning for a hygienic environment - has never been found. But after researching recent product developments in the floors specified for use in hospital and food production facilities, the architects proposed a combination of ceramic tiles designed for use in wet (pool) change areas and an innovative HT coating which offer multiple advantages over standard structured or ribbed anti-slip tiles.

The team will monitor the success of this system with a view to using it in other projects, says Swift.

Extensive facilities

With its extensive range of facilities, the council says that Sapphire Ice and Leisure will help with the regeneration projects taking place in the borough while acting as an activity hub for the local community giving more people the opportunity to get active. It will also help in the implementation of the council’s sports strategy, which incorporates ice, aquatic and sports development.

FACILITIES

Ground floor

First floor

Second floor

Third floor:

ELECTRICAL DESIGN

REL Building Services carried out all of the electrical works at the centre. The team was involved in the electrical design from the early stages, responsible for developing the concepts and evolving them as the project progressed to ensure maximum efficiency and performance.

"Initially our focus was on value engineering, ensuring the electrical elements could perform effectively within the required budget. As the timing of the project shifted, so did the design with a greater emphasis on lighting performance and more use of LED" explains Steve Jamieson, technical manager at REL Building Services.

From the original 2012 design to the final installation in 2017, there had been a considerable revolution in LED lighting technology. By reviewing the lighting design, the team managed to significantly improve both design performance and running costs".

"The ice rink and the swimming pool were built in a double height space, so the lighting had to be installed seven metres high. In the ice-rink, we used high-bay LED luminaires coordinated with AV equipment gantries that ensure good uniformity over the rink and minimise glare, which is essential for sports events" he says.

There were similar requirements for the swimming pool. The original architectural design comprised downlights around the pool perimeter, but REL changed this to ensure compliance with Sport England and to reduce maintenance. The company used LED uplighters instead and arranged them to ensure no glare on the water, maximising safety. This was achieved by directing all the light evenly over the ceiling; thereby the ceiling effectively becomes the luminaire.

Outside of the building, REL delivered lighting to harmonise and emphasise the architectural cladding, giving the facility its unique appearance.

"We had to create a vertical ribbon of light at specific points, comprising a very thin watertight LED strip just 16mm wide. This was installed between two panels to give the desired effect. We also advised on the use of cool-white LED lights to set off the blue panelling and give maximum impact"